CodeLab Participation at IASS 2025

CodeLab had a strong presence at the 2025 IASS Annual Symposium in Mexico City, contributing to this year’s theme, “The Living Past as a Source of Innovation.” CodeLab researchers Sohyun Jin and Jiaying (Vina) Wei presented new papers exploring computational approaches to structural assembly, ranging from “minimal making grammars” to stability-aware robotic construction. Here are the details of their contributions.

Jiaying Wei Presents “Stability-Aware Robotic Assembly Strategy” at IASS 2025

CodeLab researcher Jiaying (Vina) Wei presented her work at the 2025 IASS Annual Symposium via a recorded presentation. Her paper, co-authored with Professors Juney Lee and Joshua Bard, is titled “Sequencing optimization of stability-aware robotic assembly for discrete frame structures.”

The research investigates a novel computational pipeline for scaffold-free construction. By integrating iterative finite element analysis, the team developed a method to optimize the sequence of assembly for discrete frame structures. This process enables the robot to act as a temporary rigid support during construction, minimizing structural displacement. The method was validated through case studies of funicular shell structures and a multi-robot setup, establishing a foundation for safer and more efficient robotic assembly.

Sohyun Jin Presents “Minimal Making Grammar” at IASS 2025 in Mexico City

On October 28, CodeLab researcher Sohyun Jin presented new research at the 2025 IASS Annual Symposium in Mexico City. The conference, themed “The Living Past as a Source of Innovation,” served as a fitting venue for the work, which bridges traditional craft techniques with modern computational design.

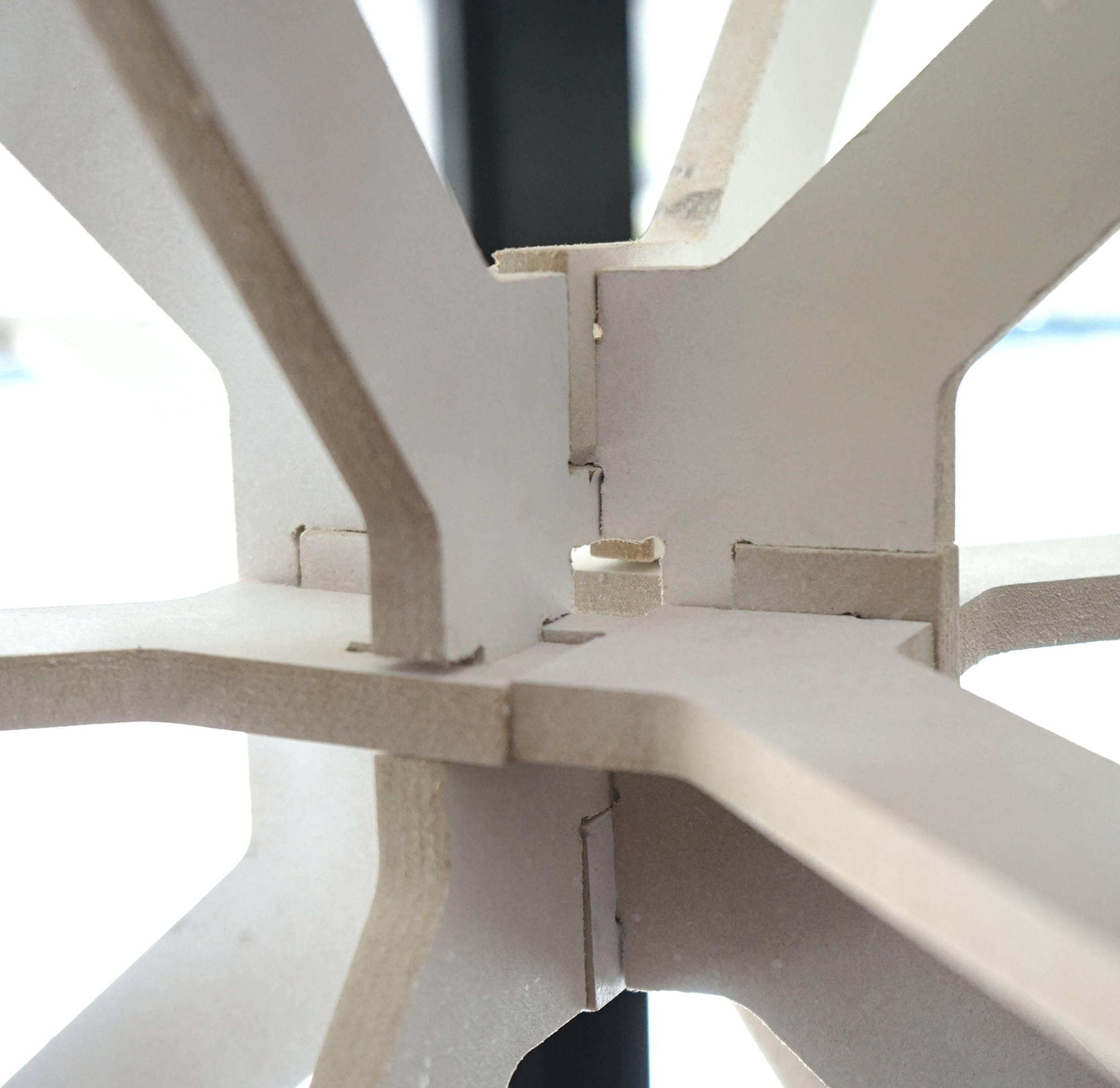

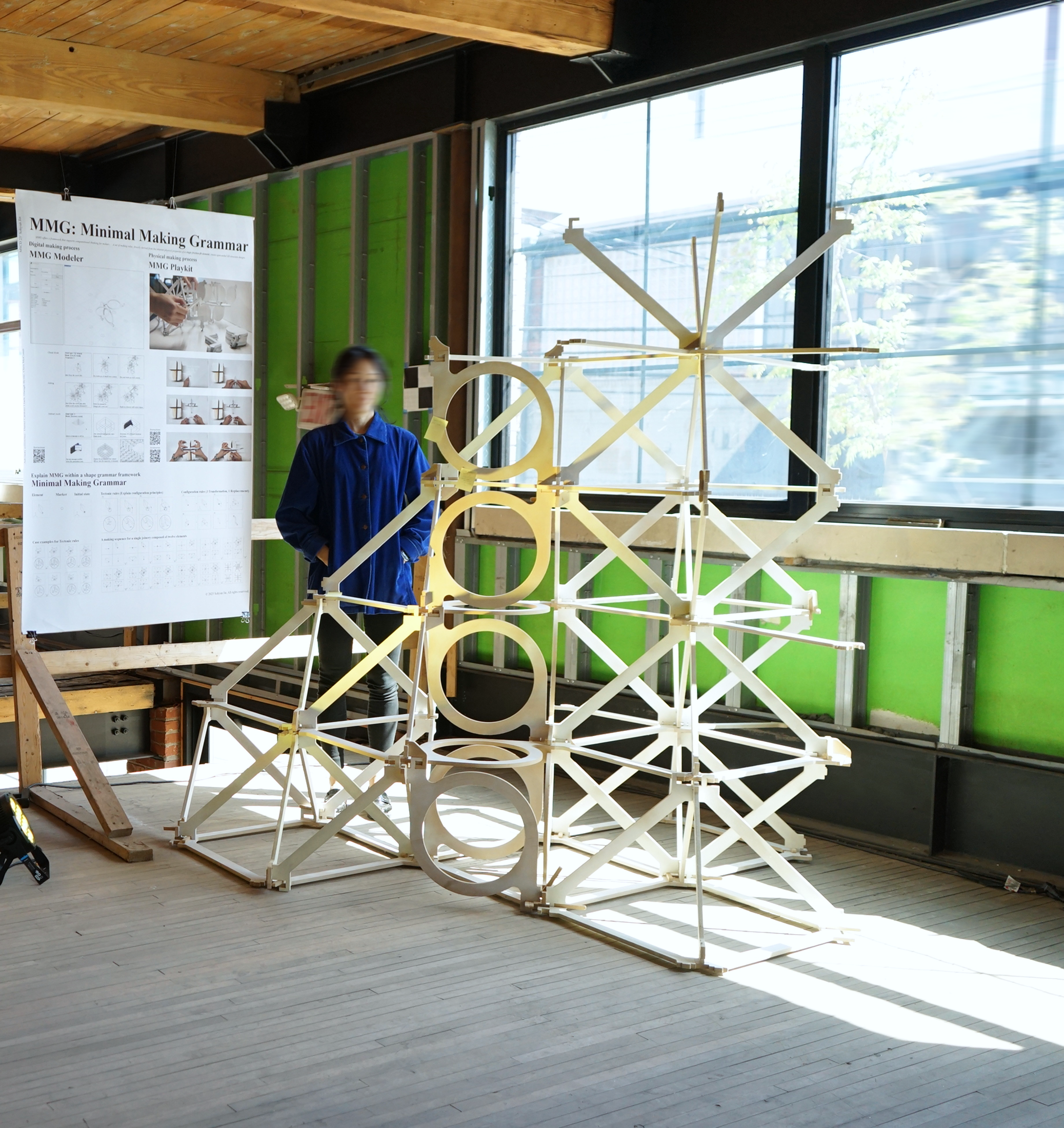

The paper, co-authored with Professor Daniel Cardoso Llach, is entitled “Design, material, and structural aspects of friction-based spatial structures: the case of a ‘minimal making grammar’.”

The research explores the structural potential of digitally fabricated, friction-based assemblies—three-dimensional structures built without fasteners, nails, or glue. By adapting traditional mortise-and-tenon joinery for modern flat-cut manufacturing, the project demonstrates a system that balances manufacturing simplicity with structural integrity. Through a combination of digital simulations and physical Instron machine testing, the team analyzed failure patterns to optimize these lightweight structures for practical architectural applications.

You can read the full paper on ResearchGate

Category: News